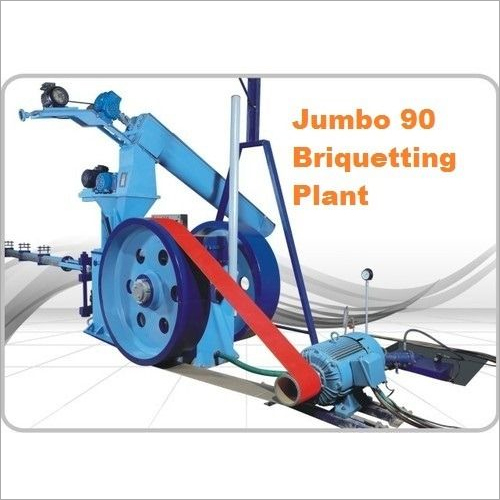

Fully Automatic Briquetting Plant

Price 1790000 INR/ Piece

Fully Automatic Briquetting Plant Specification

- Product Type

- Fully Automatic Briquetting Plant

- General Use

- Biomass Waste Briquetting, Solid Fuel Production, Industrial Applications

- Material

- Mild Steel/High Grade Steel

- Production Capacity

- 1200-2500 kg/hr (varies by model)

- Product Shape

- Cylindrical/Square Briquette

- Weight (kg)

- Approx. 6500-9000 kg

- Type

- Automatic Briquetting Machine

- Working Theory

- Mechanical Pressure Briquetting

- Computerized

- Yes

- Automatic

- Yes, Fully Automatic Operation

- PLC Control

- Available

- Cooling System

- Water-Cooling System

- Voltage

- 380 V / 415 V, 3 Phase, 50 Hz

- Motor

- 15-35 HP (varies with output)

- Roller Quantity

- 2 main pressing rollers

- Roller Diameter

- 240 mm 300 mm

- Roller Material

- Alloy Steel/Steel

- Briquette Size

- 60 mm 90 mm diameter

- Dimension (L*W*H)

- 4200 mm x 1800 mm x 1850 mm (varies by model)

- Feature

- High Efficiency, Low Maintenance, Continuous Operation

- Color

- Industrial Green/Blue (customized)

- Safety Features

- Emergency stop, overload protection, safety covers

- Output Density

- 900-1200 kg/m³ (depends on material)

- Application Materials

- Suitable for agro-waste, paper waste, coal dust, sawdust, wood chips, and more

- Operator Requirement

- Single operator required due to automation

- Feeding System

- Screw feeder with level sensor

- Lubrication System

- Automatic centralized lubrication

- Service Life

- Long operational life with minimal downtime

- Noise Level

- Low noise operation, less than 80 dB

- Hopper Capacity

- 300-500 kg

- Maintenance

- Low; easy-to-access service points

- Installation Time

- 2-4 days (site dependent)

- Control Panel

- Advanced electrical panel with safety interlocks

- Moisture Content Requirement

- 8-12% (recommended for raw material)

- Hydraulic System

- Heavy duty hydraulic pump for pressurization

Fully Automatic Briquetting Plant Trade Information

- Minimum Order Quantity

- 1 Plant

- Supply Ability

- 10 Plants Per Month

- Delivery Time

- 30 Days

About Fully Automatic Briquetting Plant

Product details of Fully Automatic Briquetting Plant

| Briquette Shape | Square, Round, Hexagonal |

| Automatic Grade | Semi-Automatic |

| Production Capacity | 500-1000 kg/hr |

| Power | Electric |

| Plant Type | Crank Type |

| Finished Product Size | 60 mm Diameter |

| Finished Product Shape | Cylindrical |

| Finished Product Length | 6" to 12" |

Robust Automation and User-Centric Design

This briquetting plant streamlines operations using a screw feeder with level sensor, advanced PLC-based control panel, and centralized lubrication system. As a result, only one operator is needed to manage the fully automated process, making it ideal for industries seeking to minimize labor costs and human error.

Superior Performance and Adaptability

Designed to work with diverse materials, the plant efficiently transforms agro-waste, sawdust, wood chips, coal dust, and even paper waste into dense briquettes. Capable of producing 9001200 kg/m briquettes at up to 2500 kg/hr, it accommodates various briquette shapes and sizes, with consistent results across production shifts.

Ease of Installation, Operation, and Maintenance

Installation can be completed within 24 days, depending on site conditions. Maintenance is straightforward, with easy-to-access service points and built-in safety features including emergency stop, overload protection, and safety covers, ensuring both user safety and low downtime.

FAQs of Fully Automatic Briquetting Plant:

Q: How does the fully automatic briquetting plant process raw material into briquettes?

A: The plant uses a mechanical pressure briquetting system, where raw material (with an 812% moisture content) is fed via a screw feeder with level sensors. The material is compressed under high pressure by twin rollers, forming dense, uniform briquettes with a typical output density of 9001200 kg/m.Q: What applications and materials are suitable for this briquetting plant?

A: This machine is versatile, handling agro-waste, sawdust, wood chips, coal dust, and paper waste. It is widely used for biomass waste briquetting, solid fuel production, and industrial heating applications in various sectors.Q: When is maintenance required, and how is it performed?

A: The plant is designed for low maintenance with easily accessible service points. Routine checks, such as refilling the centralized lubrication system and inspecting safety covers, are recommended according to periodic schedules or when prompted by the control panel.Q: Where should the plant be installed, and how long does installation take?

A: The plant is suitable for industrial or commercial spaces with proper electrical supply (380 V/415 V, 3 phase). Installation typically takes 24 days, depending on specific site conditions such as layout and foundation readiness.Q: What are the safety features included in the machine?

A: Safety is paramount, with features such as emergency stop buttons, overload protection, safety covers, and advanced electrical interlocks on the control panel. These systems ensure safe operation and rapid response in case of irregularities.Q: How does automation benefit plant operators and productivity?

A: Full automation allows operation with a single operator, enhancing efficiency, reducing labor costs, and minimizing operational errors. The advanced PLC system and level sensors further streamline the process while maintaining consistent briquette quality.Q: What are the advantages of using this plant for fuel production?

A: Users benefit from high throughput (up to 2500 kg/hr), low noise operation, minimal maintenance, and durable construction. The plant enables efficient conversion of waste materials into high-density solid fuel, promoting sustainability and cost savings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Briquetting Plants Category

Fuel Briquetting Plant

Price 2100000 INR / Piece

Minimum Order Quantity : 1 Piece

Production Capacity : 10001500 Kg/hr

Renewable Biomass Briquetting Plant

Price 1790000 INR / Plant

Minimum Order Quantity : 1 Plant

Automatic : Yes

Computerized : Yes

Renewable Energy Briquette Plant

Price 2100000 INR / Piece

Minimum Order Quantity : 1 Piece

Production Capacity : 10001500 Kg/hr

General Use : industrial

Energy Biomass Briquetting Plant

Price 2100000 INR / Piece

Minimum Order Quantity : 1 Plant

Production Capacity : 5001000 kg/hr,10001500 kg/hr Kg/hr

Automatic : No

Computerized : No

General Use : Industrial

Send Inquiry

Send Inquiry