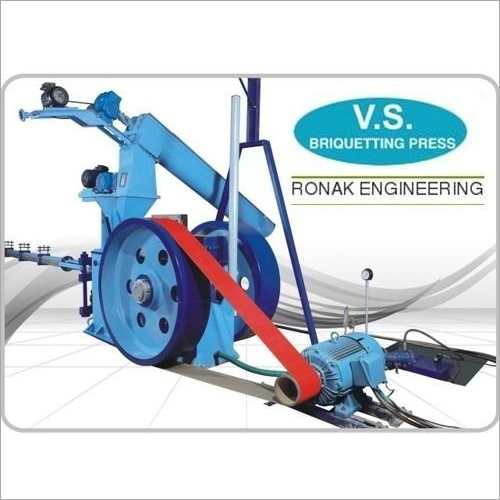

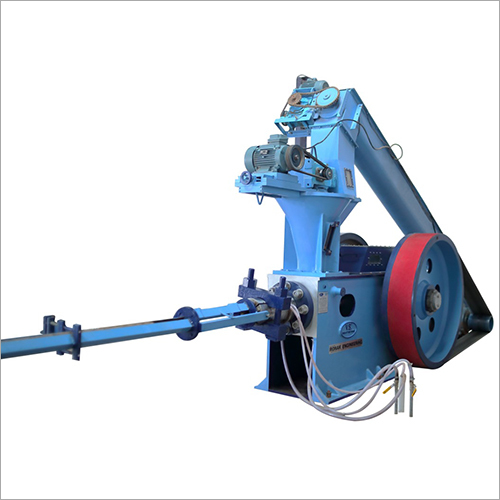

Sugarcane Bagasse Briquetting Machine

Price 2100000 INR/ Piece

MOQ : 1 Piece

Sugarcane Bagasse Briquetting Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Mundra

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 30 Days

- Packaging Details

- Standard Packaging

- Main Export Market(s)

- Australia, North America, Middle East, South America, Western Europe, Africa, Central America, Eastern Europe, Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001-2015 CE CERTIFICATE

About Sugarcane Bagasse Briquetting Machine

Owing to vast industry experience and in-depth market knowledge, we have emerged as the noted manufacturer, exporter and supplier of Sugarcane Bagasse Briquetting Machine. We can also design this machine according to the type of waste available locally. Sugarcane Bagasse Briquetting Plant is used to make briquettes from agriculture waste and forestry waste by compressing and binding the raw material from powder/ stalks /granular form to solid form by heating it using high pressure. Apart from this, Sugarcane Bagasse Briquetting Plant does not even require any external source for heating or generating pressure.Sugarcane Bagasse Briquetting Machine Technical Specifications:

1) Raw Material form: powdery,up to 25mm size can be used directly2) Power Require for Machine,Hammer,Blower: 91 H.P

3) Machine name: Biomass briquetting plant

4) Density of Briquette: 1100-1400kg approx.

5) Diameter of Briquette: 70/80/90mm approx.

6) Briquette shape: square,round,hexagonal

7) Motor & electric closet: high quality

8) Finished product Size: 60mm Diameter

9) Finished Product Length: 6" to 12"

10) Finished Product Shape: cylindrical

11) Length of Briquette: as per order

12) Production Capacity: 1000 - 1500 kg/h

13) Machine color: as per order

14) Plant type: crank / ram type

Sugarcane Bagasse Briquetting Machine Advantages:

1) Maximum production capacity2) Power consumption

3) Low maintenance cost

4) All type of raw material suitable for JUMBO-90 also sugarcane bagasse is also suitable

5) Easy in handling Briquettes due to large size of briquettes

6) Ideal for boiler operator & firemen

Sugarcane Bagasse Briquetting Press Features:

1) Ideal for use with a wide variety of forestry and agricultural wastes.2) Jamming free operations with minimal noise.

3) Optimum performance due to high speed motorized system.

4) Lesser maintenance and cleaning of chamber.

Countries we export: Kenya, Uganda, South Africa, India, Ethopia, Vietnam, Thailand

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Briquetting Machine Category

Straw Briquetting Machine

Price 2100000 INR / Piece

Minimum Order Quantity : 1 Piece

Production Capacity : 5001000 kg/hr,10001500 kg/hr Kg/hr

Material : Steel

Type : Straw Briquetting Machine

Jute Briquetting Machine

Price 2100000 INR / Piece

Minimum Order Quantity : 1 Piece

Production Capacity : 10001500 Kg/hr

Type : Briquette Machines, Briquette Press, Coal Briquetting Plant

Agriculture Waste Briquetting Machine

Price 2100000 INR

Minimum Order Quantity : 1

Production Capacity : 5001000 kg/hr,10001500 kg/hr Kg/hr

Material : Other

Send Inquiry

Send Inquiry