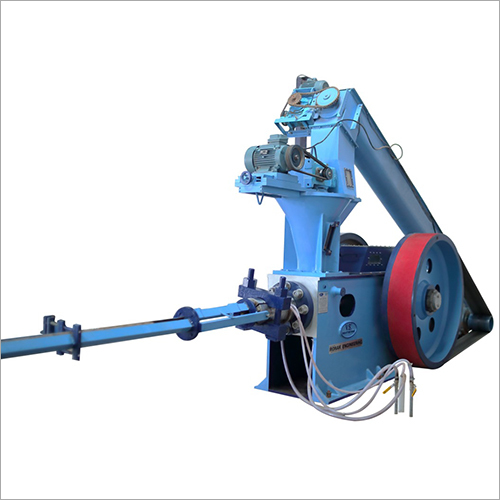

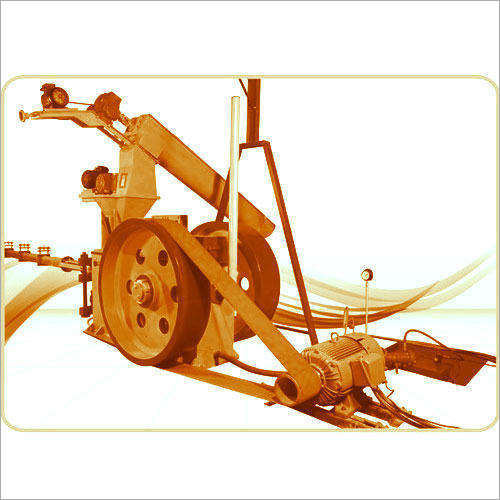

Rice Husk Briquetting Machine

Price 2100000 INR/ Piece

Rice Husk Briquetting Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Mundra

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 30 Days

- Packaging Details

- Standard Packaging

- Main Domestic Market

- All India

- Certifications

- ISO 9001-2015 CE CERTIFICATE

About Rice Husk Briquetting Machine

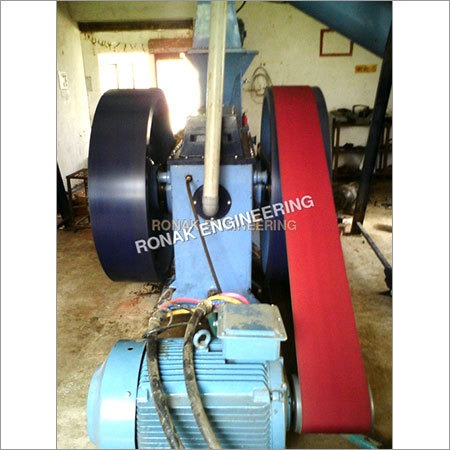

With a focus on customer satisfaction, our company, Ronak Engineering, offers rice husk briquette machine. Our production team fabricates it with top-quality metallic and non-metallic components. This machine is widely appreciated by clients for its reliability. Various quality tests are performed on machine by expert technicians to ensure flawlessness. We assure our clients of timely delivery of this machine at their premises, owing to our world-wide distribution network. Rice Husk Briquetting machine is acclaimed by clients for its following features:

- A high level of efficiency

- It requires little maintenance

- Installation is easy

- Strong construction

- Longer functional life

- Lowest operating costs

Rice Husk Briquetting Machine Technical Details:

- Rice Husk Briquetting Machine Technical Details:

- Machine name: Renewable Briquetting Machine

- Density of Briquette: Approximately1100-1400kg

- Diameter of Briquette: Approximately 70/80/90mm

- Briquette shape: Square, Round, Hexagonal

- Production Capacity: 1000-1500 kg/hr

- Motor & electric closet: High quality

- Finished Briquette Size: 60mm Diameter

- Power Require for Machine: 91 H.P

- Finished Briquette Length: 6" to 12"

- Finished Briquette Shape: cylindrical

- Length of Briquette: As per order

- Machine color: As per order

Materials used in Rice Husk Briquette Machine:

There are a variety of materials that could be used to make briquettes in addition to risk husk, including waste from rural areas and ranger services. The materials include groundnut shells, mustard shells, castor seed shells, tamarind paste, coconut husks, bamboo dust, wood chips, sugarcane waste, sawdust, tea waste, wheat straws, jute waste, paddy husks, etc. Approximately 25-30% of these can be blended with saw dust.

- Overall width of the machine- 2 meters

- Overall length of the machine- 6 meters

- Form of raw material- Powder

- Total weight of the machine- 7000 kg

- Open space- As per the requirement

Rice Husk Briquetting Machine Features:

- It takes 75 HP to run a press, blower, and hammer

- A variety of forestry and agricultural wastes can be used for producing briquettes

- Operation free of jamming and with minimal noise

- The high-speed motorized system provides optimum performance

- Less cleaning and maintenance of the chamber requires

Rice Husk Briquetting Press Advantages:

- It is cheaper to buy briquettes than coal

- It is not possible to replace oil, coal, or lignite once it has been used

- As Briquettes do not contain sulfur, they are not polluting

- The practical thermal value of biomass briquettes is higher

- In comparison to coal, briquettes have a much lower ash content (2-10%)

- Because briquettes are dry and dense, they yield better boiler efficiency

- Briquettes are simple to store, pack, and handle

- Combustion is more uniform than that of coal

Countries We Export: Kenya, India, Ethiopia, Vietnam, Uganda, South Africa, Thailand

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Husk Briquetting Machine Category

Coffee Husk Briquetting Machine

Price 2050000.0 INR / Plant

Minimum Order Quantity : 1 Plant

Pressure Form : Hydraulic Pressure

Computerized : No

PLC Control : No

Semi Automatic Rice Husk Briquettes Machines

Price 2100000 INR / Plant

Minimum Order Quantity : 1 Plant

Production Capacity : 1500 Kg/hr

Pressure Form : Hydraulic Pressure

Computerized : Yes

PLC Control : No

Mustard Husk Briquetting Machine

Price 2100000 INR

Minimum Order Quantity : 1

Production Capacity : 5001000 kg/hr,10001500 kg/hr Kg/hr

Send Inquiry

Send Inquiry