- Home Page

- Company Profile

-

Our Products

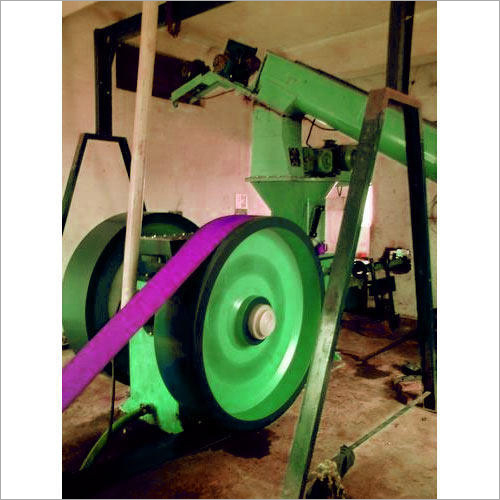

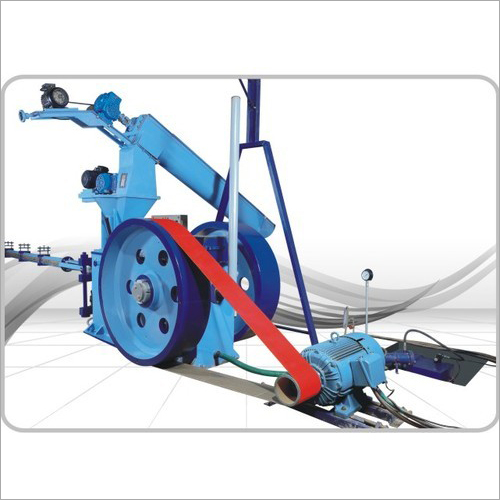

- Briquetting Machine

- Agro Waste Briquetting Machine

- Sawdust Briquetting Machine

- Jute Briquetting Machine

- Sugarcane Bagasse Briquetting Machine

- Straw Briquetting Machine

- Biomass Fuel Briquetting Machine

- Groundnut Shell Briquetting Machine

- Hydraulic Briquetting Machine

- Jumbo Briquetting Machine

- Wood Chips Briquetting Machine

- Coir Pith Briquetting Machine

- Manual Briquetting Machine

- Semi Automatic Briquetting Machine

- Automatic Biomass Briquette Machine

- Agriculture Waste Briquetting Machine

- Biomass Briquette Machine

- Briquetting Plants

- Briquetting Press

- Briquettes Making Machine

- Husk Briquetting Machine

- Biomass Dryers

- Crusher Machine

- White Coal Machine

- Briquetting Machine

- E- Catalog

- Briquetting Plant

- Contact Us

Showroom

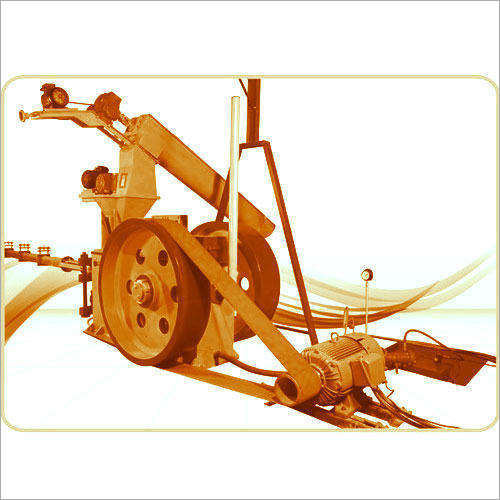

We offer an array of Briquetting Machines that are manufactured by experts by making use of superior grade components. The machines are tested extensively along various performance parameters and are offered at the best prices in the market.

We offer a range of Fuel Briquette Machine that have a long service life and do not require maintenance on a regular basis. The machines undergo stringent testing prior to being offered to customers and are thus free from defects.

Briquetting Press are heavy industrial machineries that are designed for the faster production of small sized briquettes in large volumes. There are many different variants of such machines availed by our company as per their production capacity.

Briquettes Making Machine availed by our company is designed as per the industrial standards that make them highly durable as well as efficient in operation. These machineries require an alternating voltage of 220 to 440 volts energize the driving elements.

Husk Briquetting Machine are high speed electrically powered press that are used for the compaction of grounded mixture of coal dust, husk and organic waste for the production of biofuels. These are commonly used as waste management units.

We are dealing in the manufacturing and supplying of heavy duty and efficient Biomass Dryers that are designed as per the industrial standards by our team skilled professionals. These systems make it very easier to remove the moisture from large volume of grounded bio fuels.

We are one of the leading manufacturer and supplier of high performance Crusher Machine that are designed for the restoration and recycling industries to reduce the size of the hard objects by continuous hammering with the help of high speed rotating hammers.

RONAK ENGINEERING

Contact Details

13, Galaxy Industrial Estate, Survey No. 275, Nr. Grevity Casting, Shapar (Veraval),Rajkot - 360024, Gujarat, India

Phone :08041091800

Fax :91-2827-252301

|

RONAK ENGINEERING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |